-

The Advantage of CNC Laser Cutting

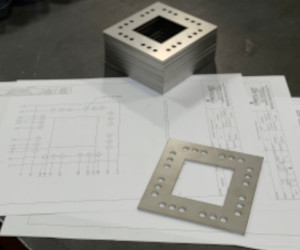

Computer Numerical Control (CNC) uses computer instruction based technologies to ensure the highest level of accuracy for a project. This allows for a highly precise laser cut capable of producing parts to tight tolerance. Laser CNC machines can product intricate designs and cuts across a range of metal material surfaces. Ideal for signage and specialty parts that require intricate cuts.

-

Reduced Production Time

Another key advantage of the CNC laser process is the ability to deliver a complex job in a shorter time frame. With computer automation and precision, the project can be executed with a higher instance of accuracy and an overall reduction in material distortion. This process reduces the need for excess additional finishing and tooling to meet the required standards of the project and the finished parts.

-

Fiber CNC Laser Cutting Advantages

Leveraging newer technologies via fiber optics, Fiber CNC Laser cutting offers a faster solution to traditional CNC laser processes. Here at Fireblast Global we use the Ermaksan Fiber Laser giving us the ability to execute jobs with a shorter lead time and a cleaner overall laser cut. This makes for the ideal conditions to product more intricate metal parts with a shorter production time. From planning to delivery, we are here to help ensure your CNC Laser Project is completed with the highest quality.

GET STARTED TODAY WITH FIREBLAST

Have a unique sheet metal fabrication project? Fireblast Fabrication has the tools and experience to help bring your project to life including precision laser cutting services.